Case

Contact

Add:Room 601-606, Building 5, No. 58, Chongchuan Road, Chongchuan District, Nantong City, Jiangsu Province

Contact: Gu Bin

Mobile phone:

Tel: +86-513-85326870

E-mail: ntlg@ntlg.cn

Project description: The Project uses 5G industrial route. The AGV trolley and industrial PDA are networked through wifi. Log in the RCS system from the PC terminal to draw maps, plan handling routes, set tasks, issue AGV trolley call, or carry out the point-to-point task handling rack through the hand-held terminal PDA. The trolley is equipped with automatic obstacle avoidance. The trolley shall automatically return to the charging pile for charging if the electric quantity is lower than the setting percent. Reduce manual handling and realize automation management.

View detailsShanghai Baosteel (Tangshan Zunhua)

The project is mainly based on Tangshan Zunhua Baosteel (hereinafter referred to as Zunhua Baosteel), which proposed a series of raw materials and semi-finished products transportation lines based on its production technology. The whole line will be composed of RGV trolley, one-way roller table and a small part of two-way roller table. Beifu CX5130 controller, TwinCAT 3 software platform, EtherCAT terminal module and ultra-high-speed EtherCAT communication are used as the intermediate carrier to connect the upper computer and RGV logistics line for communication control. Demand function: traditional transportation often encounters five headache problems: slow, chaotic, crowded, wrong and complex. Intelligent transportation solves these problems well. RGV is a kind of equipment produced with automatic transportation and storage warehouse. RGV can easily realize automatic connection with other logistics systems, such as entrance/exit platforms, various buffer stations, conveyors, elevators and robots; Deliver materials as planned. In addition, the shuttle car needs no personnel to operate and runs fast, which significantly reduces the labor workload and improves labor productivity. At the same time, the application of RGV can make the transportation system very convenient.

View detailsSanding trim line of Wangli 019 wooden door

According to the overall development planning outline of Wangli (Sichuan) Wooden Door Intelligent Plant Project of Sichuan Wangli Tefang Door Industry Co., Ltd., the production line uses the German BECKHOFF controller CX5130, EL6021 communication module, taking Twincat2 as the core of the PC control technology, integrating the upper computer, networking the third-party MES AGV logistics system, and using Kingco human-computer interactive touch screen for separate cabinets. Start production, automatic material request (wooden door), production, palletizing, unloading, and production process data collection, build a digital intelligent (2.5-3.0) plant, and realize quality improvement, cost reduction and efficiency increase.

View detailsIn this case, 6015 is used as the PLC control system, and 8 servos are controlled via Ethercat bus. The 5 axes of the workbench XYZAB work in absolute positioning mode to determine the coordinate position of the hole. Drilling servo shaft 8 works in speed mode. Servo shafts 6 and 7 transport iron wire and rubber in relative fixed length mode. In a very short time, realize the response of servo and PLC, complete the relative fixed length and hole position movement. In addition, it is also equipped with manual mode. In manual mode, the handwheel can realize static coupling with each axis, which is convenient for manual operation and commissioning.

View detailsBig data kanban of Gongpu Education in Kunshan, Jiangsu

The Project mainly consists of three sectors. The left side is the use of all equipment in the campus (startup & shutdown status, operation status, energy consumption), the middle is the talent training overview, distribution of the campus, number of college graduates last year, number of talent needs and talent gap, and the right side is the post demand, salary and recruitment information.

View detailsJiangsu Zhangjiagang Siqi Technology Co., Ltd. Big Data Kanban

The project collects real-time data through the Buke screen and writes the data into MQTT. The project function is to display the real-time production data of multiple assembly lines by rotation, including the temperature, frequency and speed of the equipment and the alarm prompt.

View detailsEquipment management board of Jiangsu Zhangjiagang Siqi Technology Co., Ltd

This item is mainly used to view equipment repair processing progress, including repair progress, audit progress, equipment failure ranking in the last 7 days, repair time ranking and downtime ranking.

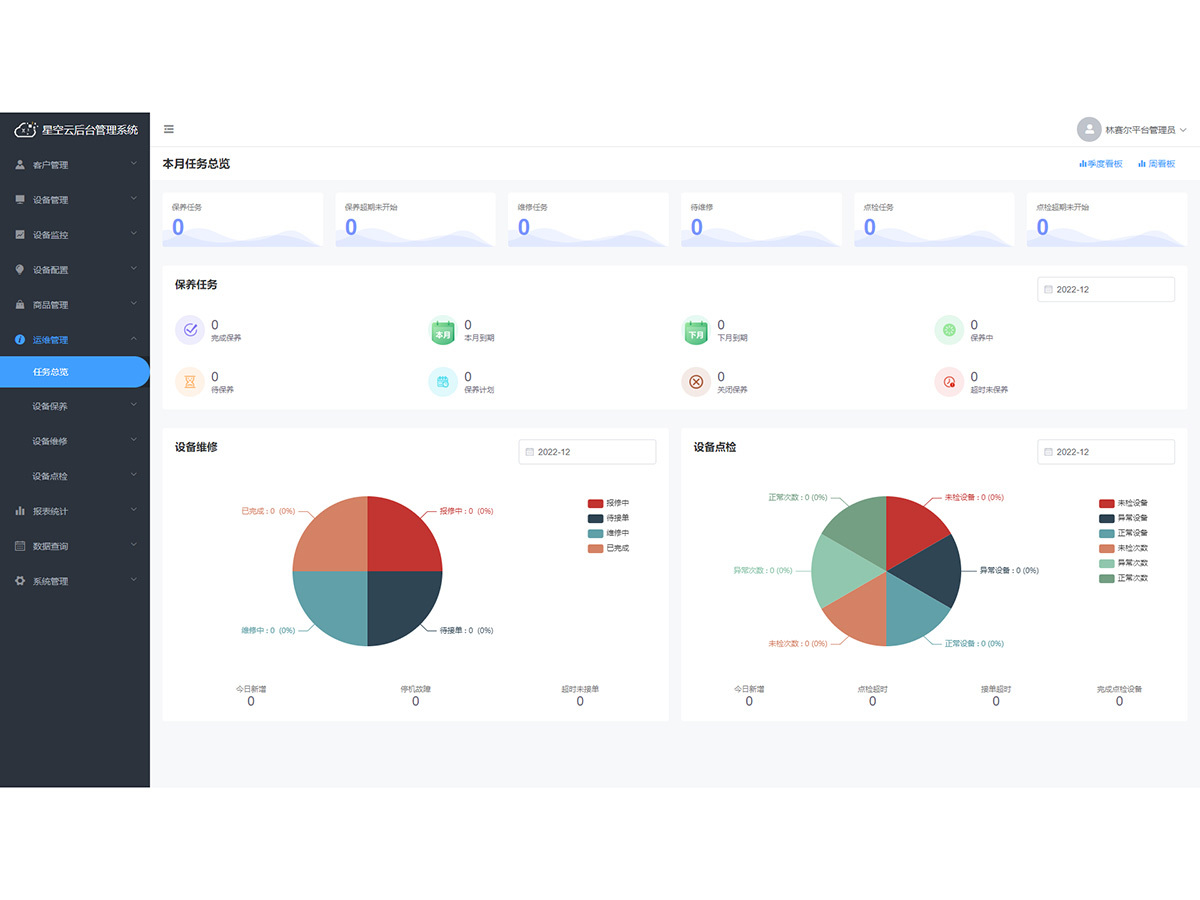

View detailsStarry Cloud Background Management System

The front and back end separation technology is used to connect all pages together and control the display of the page. Through the system, users can realize equipment management, operation and maintenance management, system user role management, statistical analysis (collected equipment status and production data) through a visual tool. Users can view and manage information at any time after logging in, more efficiently obtain information, and intelligently monitor equipment, Timely find out the fault problem, and the Star Cloud background management system can manage the operation and maintenance by means of informatization, so as to make the operation and maintenance service more efficient, safe and convenient.

View details